VIbrationnal Spectroscopiesfor Insitu and Operando

Organization

Organization and operation

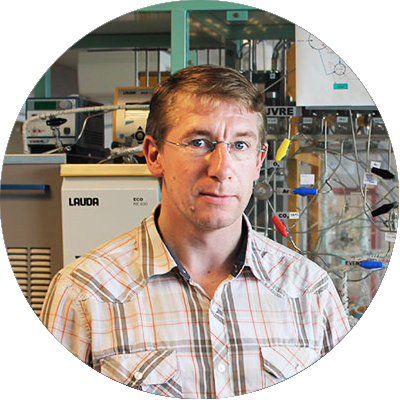

Alexandre VIMONT

Research Engineer

Philippe BAZIN

Research Engineer

Platform Manager

Yoann LEVAQUE

Design Engineer

The VISIO platform manager is Philippe BAZIN, Research Engineer.

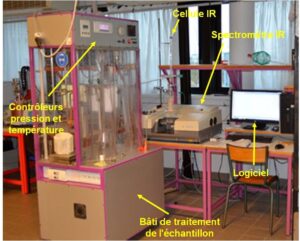

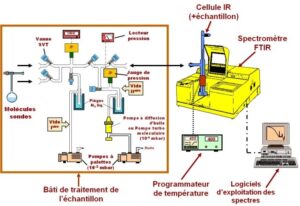

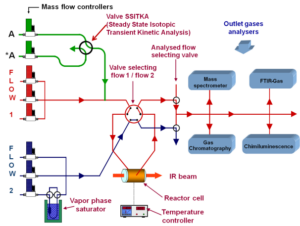

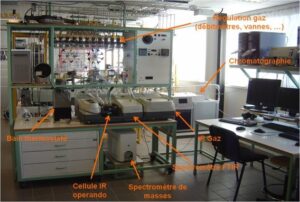

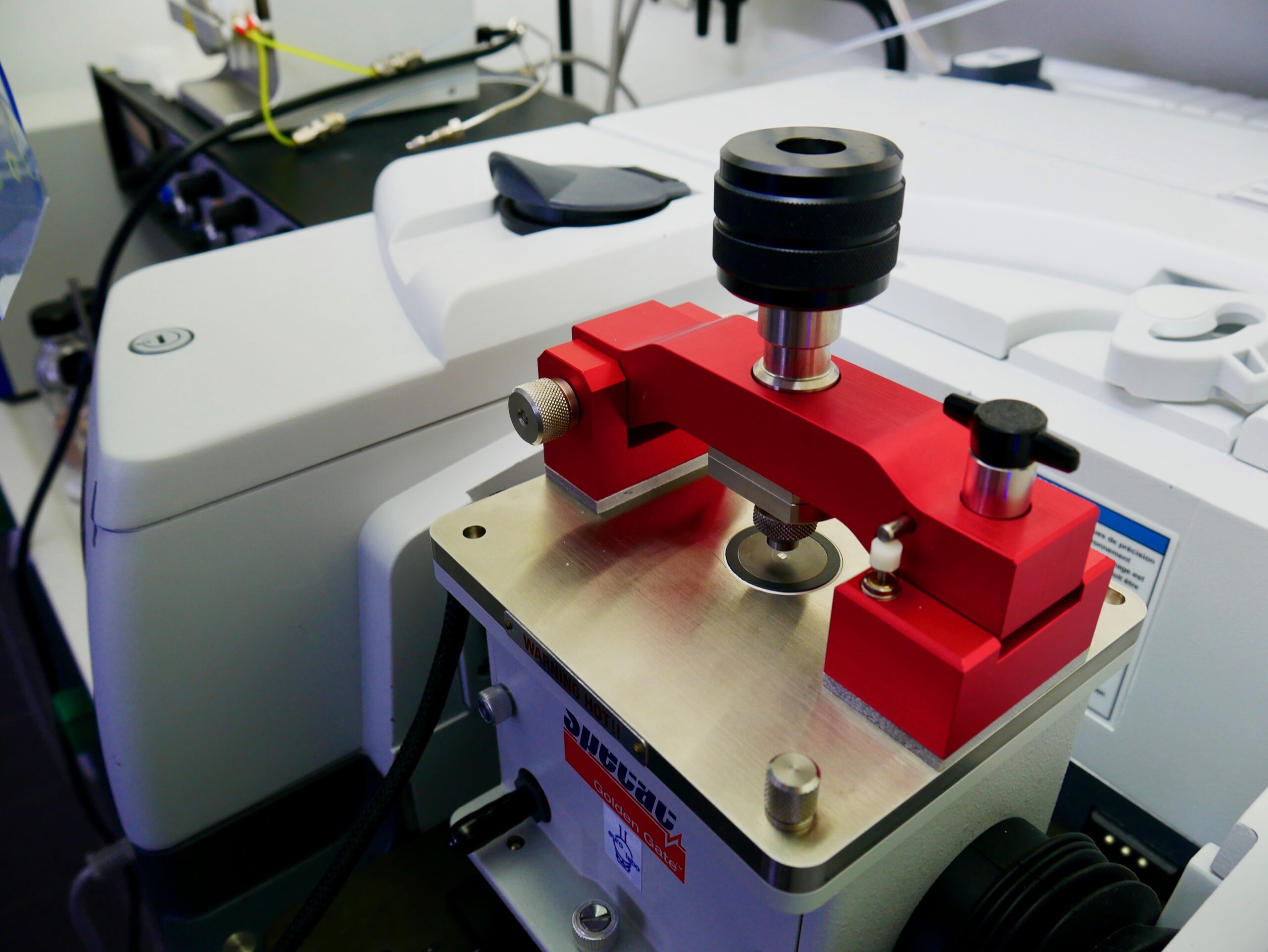

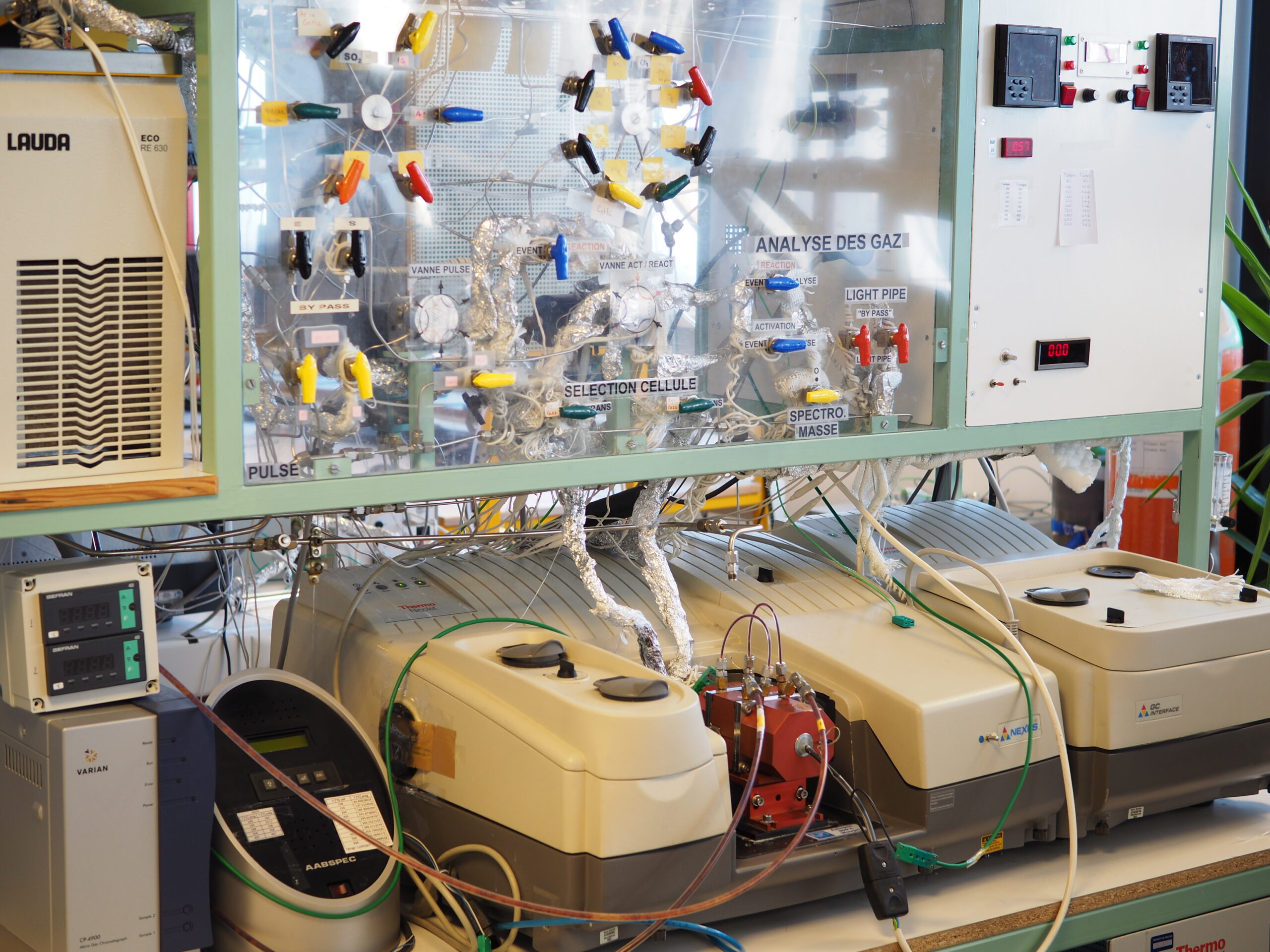

The VISIO platform, which is unique in the world in terms of the number and nature of its instruments, currently comprises a vast array of 24 UV, Raman and infrared spectrometers. The VISIO platform comprises 24 workstations dedicated to different spectroscopic measurements. A schematic view of the platform is shown below, with an inset photo of one of the IR operando spectroscopy workstations.

Five people (1 PR, 2 IR, 1 IE, 1 AI) participate in the management of the platform via a steering committee, and are responsible for ensuring the smooth operation of all the equipment at each workstation, managing usage schedules, training users and developing tools.

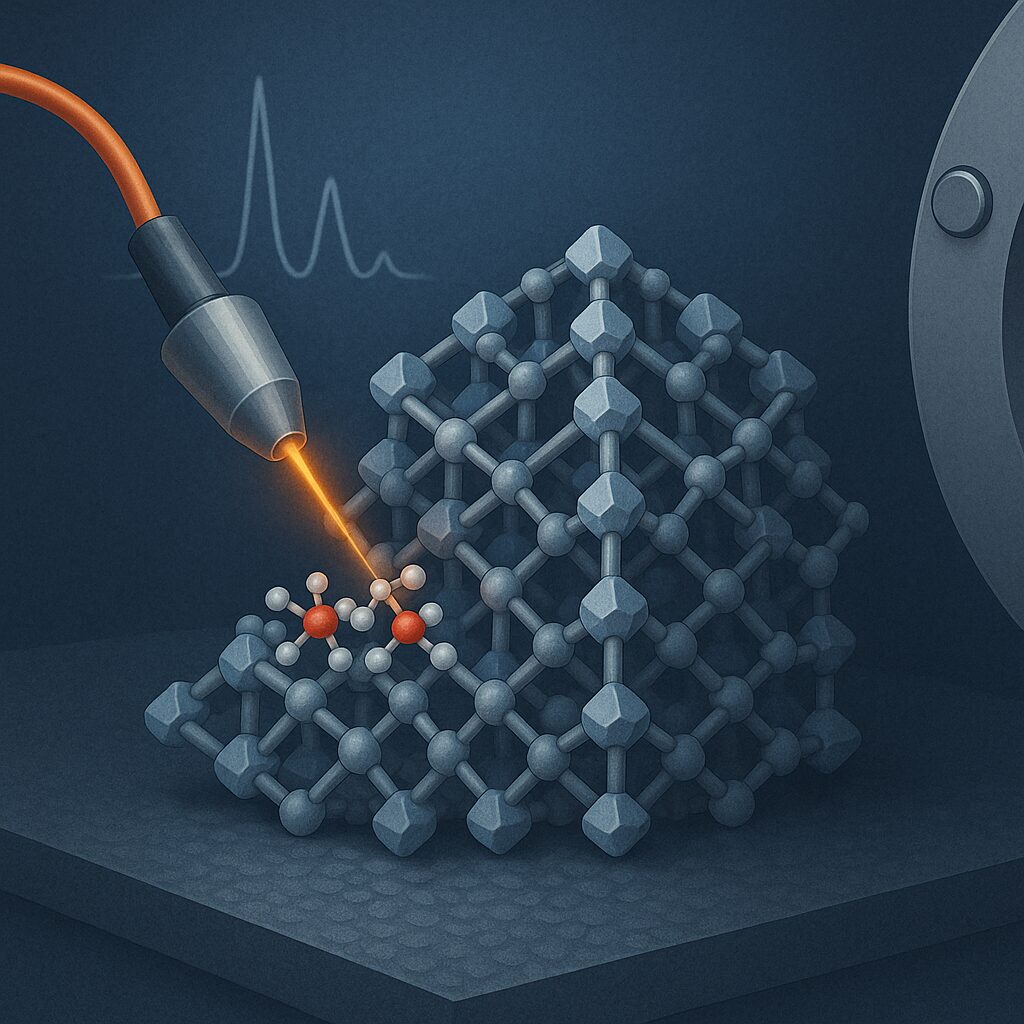

In situ IR spectroscopy

Observe molecular interactions and surface properties in a controlled atmosphere

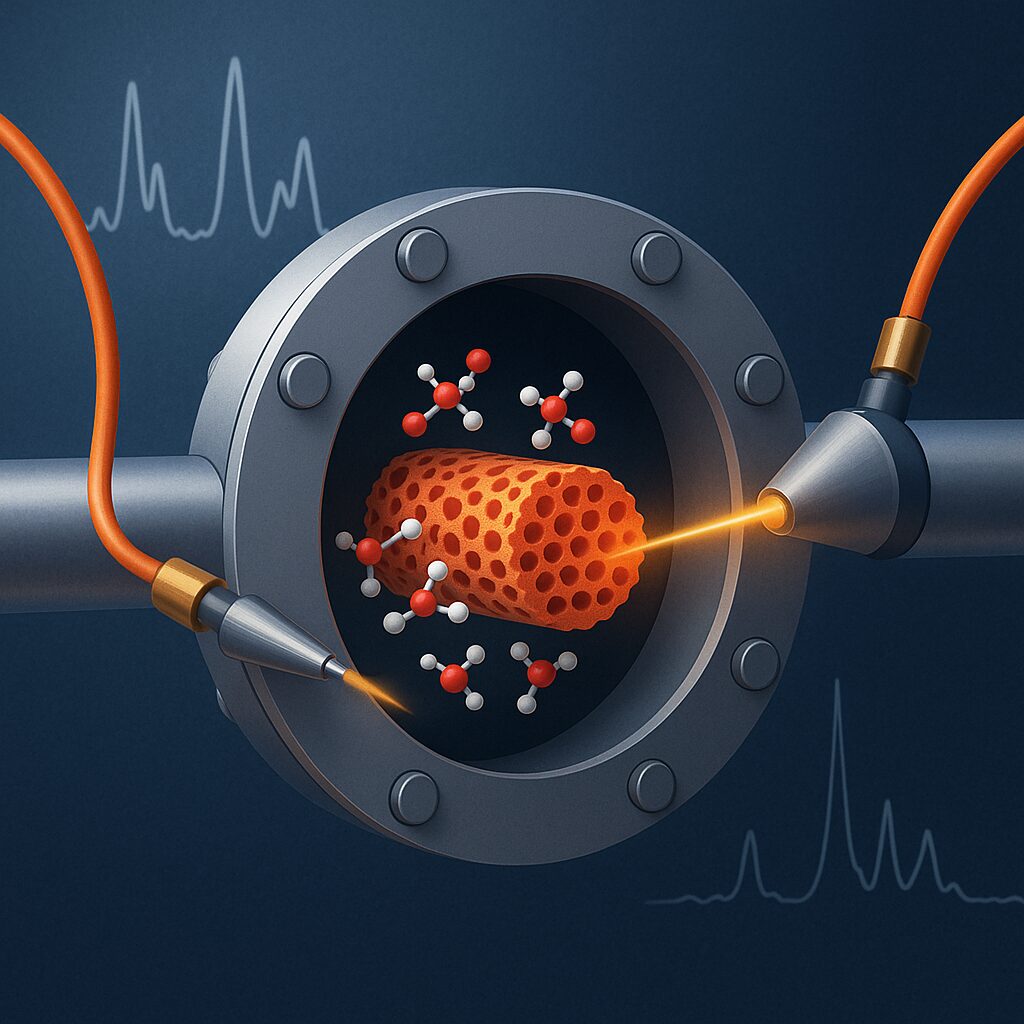

IR operando spectroscopy

Analyze reaction mechanisms under conditions close to industrial processes.

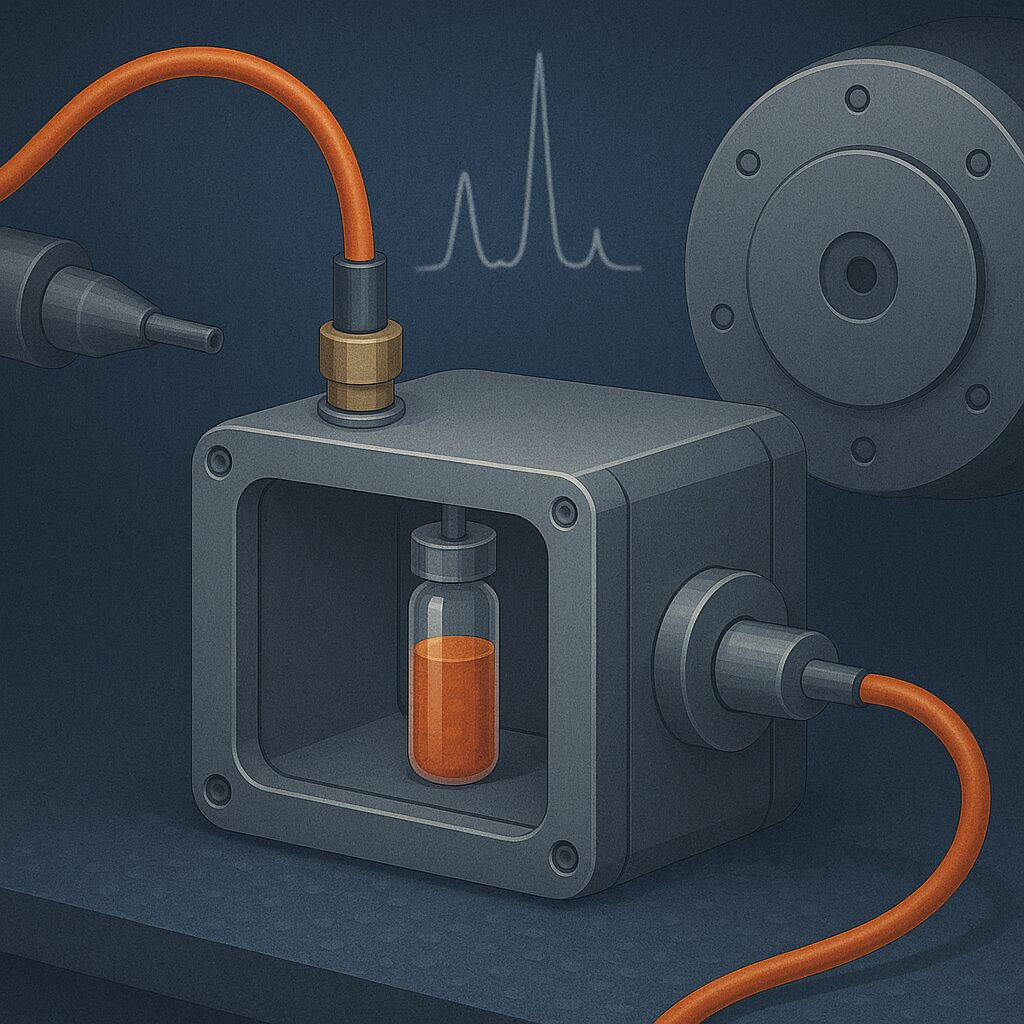

Innovative cells and couplings

Develop unique experimental set-ups for advanced analysis.

Missions

Observe, Understand, Innovate

Provide all researchers with the spectroscopic tools they need to understand how catalysts work at the molecular level.

Development enables us to offer unique, high-performance research tools tailored to the LCS’s research activities.

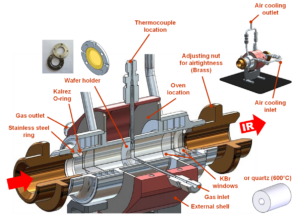

In situ and operando analysis of materials under real conditions of temperature, pressure and atmosphere, to understand reaction mechanisms and structural evolution directly in the chemical reactor core.

equipment

Our instruments

In detail, the various items are of four types:

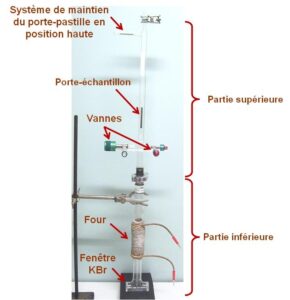

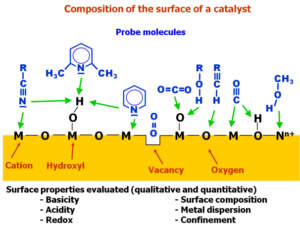

13 “IR in situ” stations dedicated to qualitative and quantitative measurements of the surface properties of materials (acidity, basicity, redox, atomic composition, metal dispersion, confinement, etc.) via the controlled adsorption of probe molecules. Some of these stations have special features:

3 “IR in situ sous flux” stations offer the possibility of pretreating samples under flux either at atmospheric pressure or at high pressure (P<50 bars),

2 IR step-scan stations for high temporal resolution experiments,

2 “IR Microscopy” stations for high spatial resolution experiments.

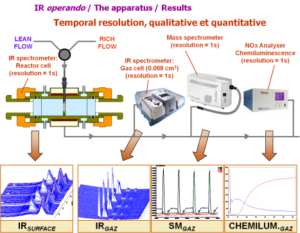

9 “IR operando” stations dedicated to the study of materials in operation under conditions of flow, temperature, pressure, etc. close to the real process. The aim is to get to the bottom of the reaction mechanisms involved by gaining a better understanding of the active sites, intermediates and spectator species.

1 “Raman Microscopy” station dedicated to measuring structural changes in materials.

1 “UV-Vis” station dedicated to measuring material structure and adsorbed species.

22 FTIR spectrometers equipped with MCT and DTGS detectors, including :

2 dedicated to rapid step-scan acquisition

2 IR microscopes for spatial acquisition

8 equipped with an auxiliary bench dedicated to gas analysis

1 equipped with elements (IR sources, detectors and separators) for near-IR and far-IR analysis.

1 Raman microscope

1 UV-Vis spectrometer

11 mass spectrometers (0-200 amu)

3 photoluminescence analyzers dedicated to NOx analysis

1 GC

1 microGC

14 cryostats : 1 x 200/-40°C, 2 x 100/-90°C et 11 x 100/-30°C

Some forty IR, Raman and UV cells adapted for in situ and operando experiments.

To go further!

InSitu

Definition: “In situ” infrared spectroscopy enables qualitative and quantitative evaluation of catalyst surface properties (acidity, basicity, redox, composition, metal dispersion, etc.) by adsorption of specific probe molecules (CO, Pyridine, CH3OH, CH3CN, CO2, Propyne, etc.).

Operando

Platform-related projects :

- LCS

- 24 887 k€ financés par Carnot ESP - AAP2021

- BAZIN Philippe

TAR-G-ED

- LCS - MACS - LASIR

- Aide de l'ANR 362 000 euros

- VALTCHEV Valentin

MOSAIC

- LCS

- Aide de l'ANR 377 984 euros

- FERNANDEZ Christian

- LCS - CRISMAT

- Lauréat Labex EMC³ AAP2016

- CLET Guillaume

DirectSynBioFuel

- UCCS - LCS

- Financé à hauteur de 329 680 € par l'ANR

- VALTCHEV Valentin

- LCS

- Financé à hauteur de 20000€ par LABEX EMC3-2025

- BARREAU Mathias

- LCS

- AAP Carnot ESP

- AL LAKISS Louwanda; VALTCHEV Valentin; EL ROZ Mohamad; GILSON Jean-Pierre

VALOPLAST

- LCS

- Ce projet est financé par une bourse UNICAEN

- AL LAKISS Louwanda; VALTCHEV Valentin

ZEOMETHYL – CALIPSO

- LCS - CORIA

- Le projet a fait l'objet d'une thése soutenue par Talla Sorelle TEMBONSO

- MAUGÉ Françoise; BAZIN Philippe; VIMONT Alexandre

CIFRE Enercat

- LCS

- Thèse de doctorat soutenu par Mathias LALUC, dirigée par Marco DATURI.

- LALUC Mathias; DATURI Marco

- LCS - IMAP - ICGM - Soleil

- Aide globale de 488510,40 €, dont 157920 € pour le LCS

- DATURI Marco; EL ROZ Mohamad

APL

- LCS

- 56K€ financés par l'institut Carnot.

- THOMAS Karine; MAUGE Françoise;

H2CO2

- LCS - CRISMAT

- Ce projet est cofinancé par l'Union européenne et la Région Normandie à hauteur de 149 850 €

- EL ROZ Mohamad [10%]

3DZEOPOL

- LCS

- 240 K€ financé par l'institut Carnot.

- EL ROZ Mohamad[10%]

HERMOS

- LCS

- Ressourcement CARNOT ESP 2020

- MAUGE Francoise [10%];OLIVIERO Laetitia [10%]

- LCS

- Ressourcement CARNOT ESP 2019

- CLET Guillaume [10%];DATURI Marco [10%]

- LCS

- Ressourcement CARNOT ESP 2018

- KOUVATAS Cassandre [10%]

ADSOCARB

- LCS

- Projet Émergence (RIN) financé par la Région Normandie.

- THIBAULT-STARZYK Frédéric [5%]; AZZOLINA-JURY Fédérico; ELGAYYAR Taha

SUNRISE

- LCS - CIMAP

- 150 K€ financé par la région normandie et l'Union Européene.

- EL ROZ Mohamad [5%]

- LCS

- 528 K€ financé par le Label d’excellence RIN RECHERCHE 2022.

- EL ROZ Mohamad

HOSMOS

- LCS - CIMAP

- Lauréat Labex EMC³ AAP2022

- OLIVIERO Laetitia [5%]; MINTOVA Svetlana [5%];

CELL-PHI

- LCS - LOMC

- Lauréat Labex EMC³ AAP2022

- TRAVERT Arnaud [5%];BAZIN Philippe [5%]; KOUVATAS Cassandre;

MAMABIO

- LCS - IFPEN

- Financé à hauteur de 2,2 M€ par le PIA

- TRAVERT Arnaud [5%];THOMAS Karine [5%];BAZIN Philippe [5%]

SIMIACCI

- LCS

- 3,9 M€ financé par l'Union Européene.

- DATURI Marco

MOF2H2

- LCS - ICGM - LOF - IMAP

- Ce projet est financé par l'Union européenne (3,2 M€) dans le cadre de la convention de subvention #101084131.

- DATURI Marco [5%];EL ROZ Mohamad [5%]

METHASOL

- LCS

- 4.0 M€ from the EU’s Horizon 2020 research and innovation programme out of a total budget of 5.2 M€

- BAZIN Philippe [10%];CLET Guillaume [10%];DATURI Marco [10%];EL ROZ Mohamad [10%];VIMONT Alexandre [10%]

MOF4AIR

- LCS

- Budget : 11.1 M€, dont 9.9 M€ de contribution de l’UE

- BAZIN Philippe [10%];CLET Guillaume [10%];DATURI Marco [10%];VIMONT Alexandre [10%]

HEI

- LCS

- Ce projet est financé par l'Union européenne et la Région Normandie à hauteur de 558 000 euros.

Nanoclean Energy

- LCS - Total

- Ce projet bénéficie d'un budget global de 2 M€, dont la moitié est apportée par TOTAL tandis que l’autre moitié est prise en charge par l’ANR

- VALTCHEV Valentin

EcoHdoc

- LCS - UCCS - LACCO

- Ce projet est financé par l'Agence Nationale de la Recherche à hauteur de 673 897 € et le FEDER.

- MAUGÉ Françoise