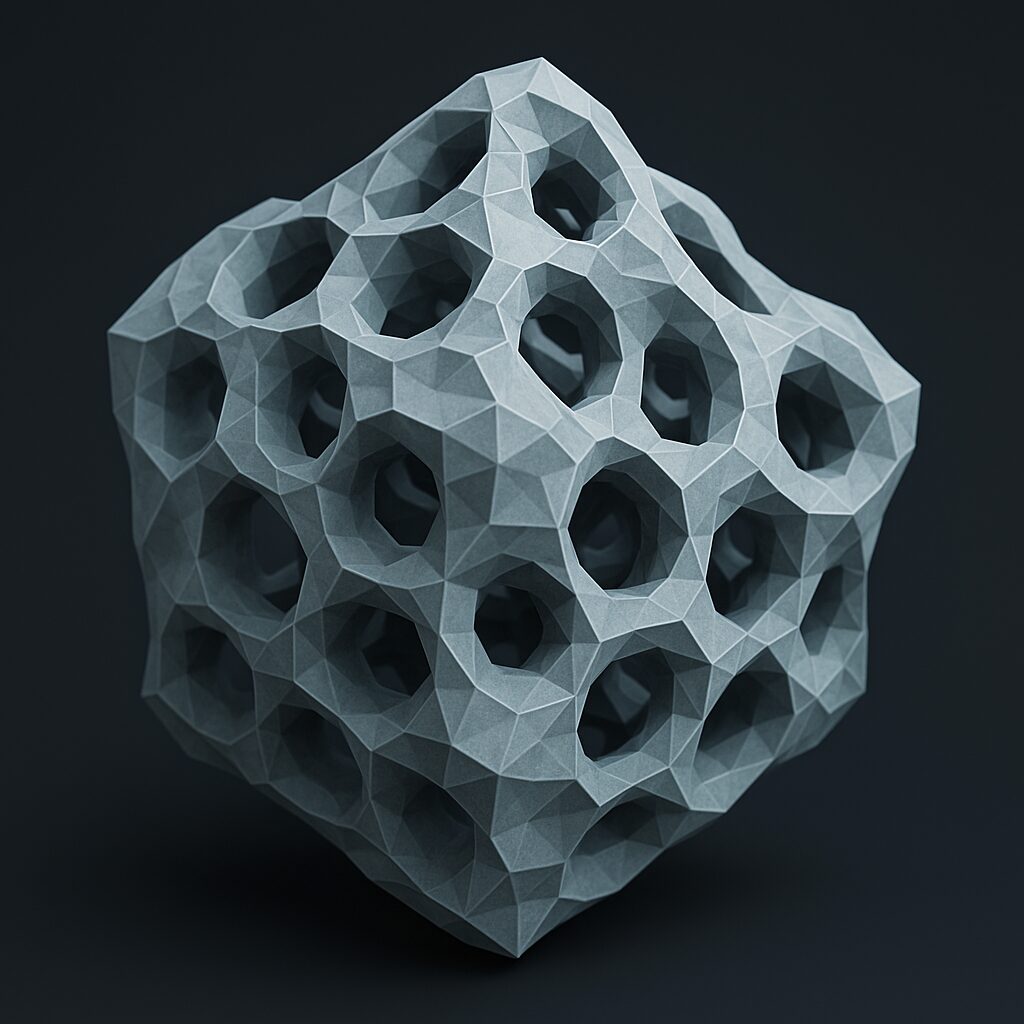

Advanced synthesis of zeolites and porous materials

Organization

Organization and operation

Valérie RUAUX

Research Engineer

Louwanda LAKISS

Research Engineer

Platform Manager

Marie DESMURS

Assistant Engineer

The synthesis and characterization platform specializes in the preparation of microporous materials (zeolites and related materials) as well as other types of oxide. It provides LCS researchers with the latest technologies for the synthesis, modification and characterization of zeolites and related porous materials. It currently comprises 2 highly-equipped preparation laboratories dedicated to sol-gel preparation (Wetlab 1 and 2), a thermal room (ovens and furnaces) and 3 rooms dedicated to physico-chemical characterization (Adsorption, ICP, Thermal Analysis, XRD, glovebox, etc.).

The platform is managed by a team of 3: two research engineers and an assistant engineer. This team ensures the upkeep and maintenance of the equipment, as well as the transfer of know-how to the various users (researchers and students).

Expertise & Missions

Advanced synthesis methods

Zeolite synthesis

Post-synthesis / analysis

Intensive batch processes

- The development of new tools to stay at the cutting edge of zeolite and porous material synthesis and characterization techniques

- Maintain existing tools and make them available to users

- Transfer of know-how to PhD students and post-docs through training in zeolite synthesis and characterization techniques

- Communicating advances in zeolite synthesis through publications and oral communications

equipment

The workspace

> Wetlab 1and 2

2 laboratories dedicated to the synthesis and modification of porous materials, equipped with a wide range of laboratory equipment adapted to the laboratory’s research projects, including 16 preparation benches, 2 centrifuges, 2 freeze-dryers, 2 Rotavap and other equipment dedicated to materials preparation such as magnetic stirrers, a microwave oven for synthesis, a rheometer, a spin coater, an extruder etc.). Both rooms can accommodate 25 people.

> Robot synthesizers

At the LCS, we have focused on material design using combinatorial/parallel synthesis, as opposed to more conventional practices. The lab now has a synthesis robot specially designed and adapted for screening the synthesis parameters of porous materials. Its automatic system can perform all the steps required to prepare the materials: preparation and stirring of the various solid and/or liquid reagents, heating as well as filtration and/or centrifugation to recover the final product after synthesis. It is equipped with various synthesis blocks with different capacities: a row of 48 20-40 ml reactors at moderate temperatures (0-100°C) and a row of 24 20-40 ml reactors at high temperatures (150-190°C). It is also equipped with a special HF pump, and a pH meter to measure and adjust pH before and after synthesis. Its software allows simultaneous control of synthesis, purification and separation of synthesized materials. This device enables sequential actions to be carried out and all reaction parameters to be recorded throughout the experiment, guaranteeing better control and reproducibility of syntheses. This is a very important tool. It enables us to save time, energy, chemicals and consumables, while maximizing the efficiency of the materials produced. It also enables us to optimize the time of team members working on any given project.

> Furnaces and ovens

5 calcination furnaces, 2 of which are equipped with a controlled atmosphere calcination system, and 7 ovens, two of which are equipped with a mechanical stirring system. All the equipment is installed in a closed room equipped with an external extraction system.

> Elemental analysis by ICP-MS (Agilent 7900)

The laboratory has an ICP-MS spectrometer (Agilent 7900) equipped with a 90-sample changer, which enables the chemical composition of a material or mixture to be determined. The combination of ICP and mass spectrometry enables the determination of a wide range of inorganic elements and elemental impurities, with extreme reliability and precision.

> X-ray Diffraction (XRD)

The platform has two X-ray diffractometers equipped with 20-sample changers (PANalytical X’pert Pro and ANTON PAAR). This enables us to identify the crystallized compound(s) present in a material, as well as their crystallographic forms.

> ATG/ATD thermogravimetric analysis

The laboratory is equipped with two thermogravimetric analysis devices (SETARAM and NEZSCH), which can be used to determine the mass loss of a material as a function of temperature (thermal cycle, ramp, gas used). One of the two instruments is coupled to a mass spectrometer and a 20-sample autosampler, while the other is coupled to an infrared gas cell. This enables us to identify and study the gaseous effluents released or the products released following thermal degradation.

> SEM

Two Scanning Electron Microscopes (GEOL and TESCAN) equipped with EDS probes enable us to study the morphology of materials and carry out elementary mapping analyses.

> Adsorption

The LCS laboratory has a fleet of gas adsorption analyzers (nitrogen, argon (with a specific cryogenic unit) and VOCs for analyzing porous and non-porous materials. The platform is also equipped with a mercury prosimeter and two devices dedicated to high-pressure adsorption experiments.