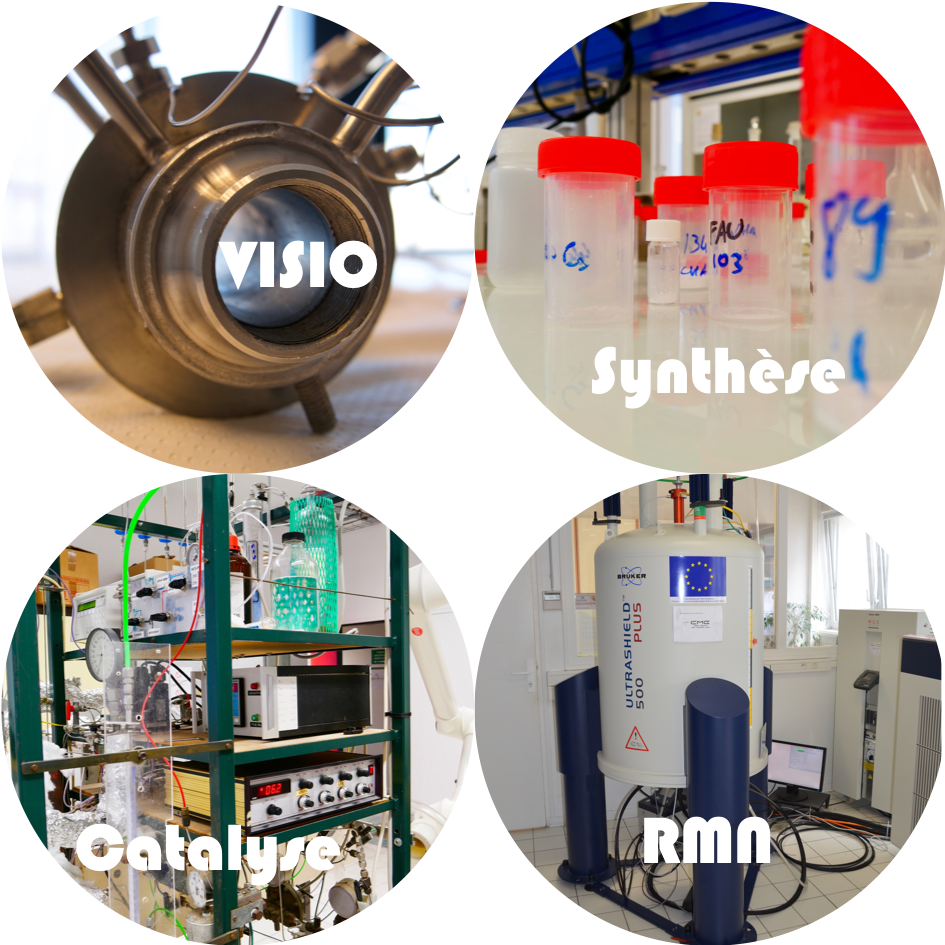

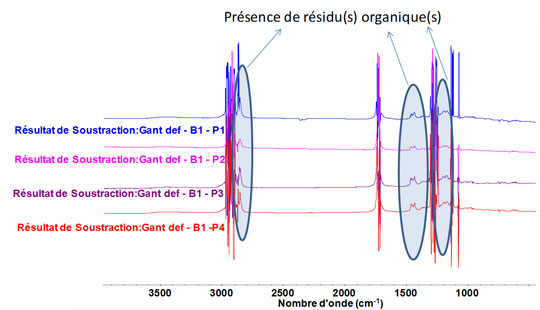

LCS Valoris offers you its expertise and flexibility for all your industrial analysis requirements and research projects.

It’s a one-stop shop where you can discuss your problems and find the best person in the laboratory to address them. Cooperation with a university laboratory gives a company access to specific skills and unique laboratory resources. What’s more, you can reduce your R&D costs as we are eligible for the Research Tax Credit (CIR).

LCS Valoris undertakes to treat your request as confidential. A confidentiality agreement can be signed before discussing the technical or commercial aspects of your project in detail.